- Home

- Woodwork Machines

- CNC Woodwork Machines

- CNC End Tenoner

CNC End Tenoner Woodworking Tenoner and Mortisier

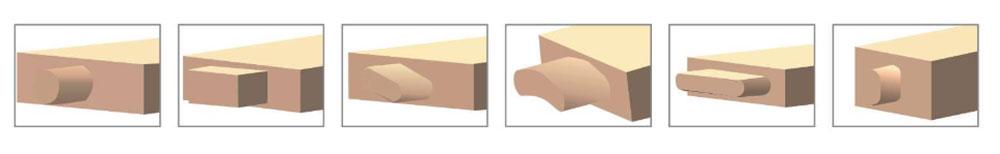

The CNC end tenoner is used to process different tenon in wooden furniture such as tables, chairs beds, and doors. Mingda’s CNC tenoner features an easy man to machine interface operation. After setting the workpiece shape via the touch screen and inputting the tenon and wooden board size in the dialog box, the process begins. It is easy and efficient.

This tenoner also uses a servo driving system, and main components, including the ball screw, linear guideway, pneumatic component, and electrical elements are imported from Taiwan to ensure the high quality and stability.

| Model | MDS-150 |

| A joint maximum width | 200mm |

| A joint thickness | 70mm |

| Maximum processing width | 45mm |

| Spindle horsepower | 3.7KW |

| Spindle revolution | 9000rpm |

| X axis servo | 750W |

| Y axis servo | 750W |

| Vacuuming mouth size | 4 Inch×3 |

| Mechanical dimensions(L×W×H) | 1750×1000×1500mm |

| Net weight | 950KG |

Send an Inquiry

If you are interested in this product, feel free to contact us anytime!

Other Products