- Home

- Woodwork Machines

- CNC Woodwork Machines

- CNC Machining Center

CNC Machining Center CNC 3-Axis Router, CNC Machines for Wood and Panels

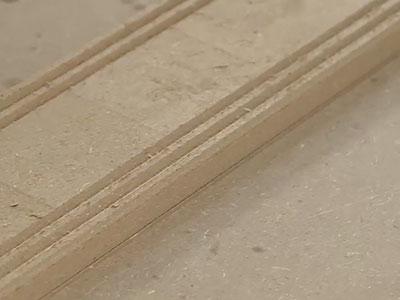

This CNC machining center features a gantry mode movement, servo driving system and Taiwanese Syntec control system to ensure a fast, accurate processing. It is widely used for wood and other drilling, reaming, milling slot, and contour machining applications with nonmetal materials. It also significantly improves the processing efficiency and yield.

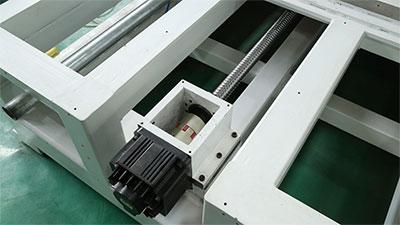

The CNC machining center is equipped with a circular tool magazine, which can store 8 knives at a time and automatically replace a knife within 6 seconds. A built-in switch system ensures a precise tool holder identification and is used for migrating tool management. Main components of the CNC machining center, including the spindle, ball screw, linear guideway, pneumatic components and electrical elements are imported worldwide from famous suppliers, with a high quality and strong stability. For example, the HSD electric spindle is from Italy, UP JOHN vacuum pump, and a Delta servo drive.

| MODEL | MD-NC1625TC1 | MD-NC1632TC1 |

| Table size | 1600×2500mm | 1600×3200mm |

| Spindle horsepower | 9.5KW×1 | 9.5KW×1 |

| Spindle revolution | 1000-24000rpm | 1000-24000rpm |

| Servo motor | 1.5KW | 1.5KW |

| 2.0KW | 2.0KW | |

| 1.0KW | 1.0KW | |

| Work schedule | 1600mm | 1600mm |

| 2500mm | 3200mm | |

| 200mm | 200mm | |

| The handle size and quantity | ISO30×8PCS | ISO30×8PCS |

| Vacuum pump | 5.5KW-250m³/H | 5.5KW-250m³/H |

| Vacuuming mouth size | 5 Inch×1 | 5 Inch×1 |

| Machanical dimensions(L×W×H) | 3600×2400×2100mm | 4300×2400×2100mm |

| Net weight | About 3200KG | About 3500KG |

If you are interested in this product, feel free to contact us anytime!